Do you know the difference between large-span and small-span steel structure plant?

Analysis of the differences and characteristics of large-span and small-span steel structure plants

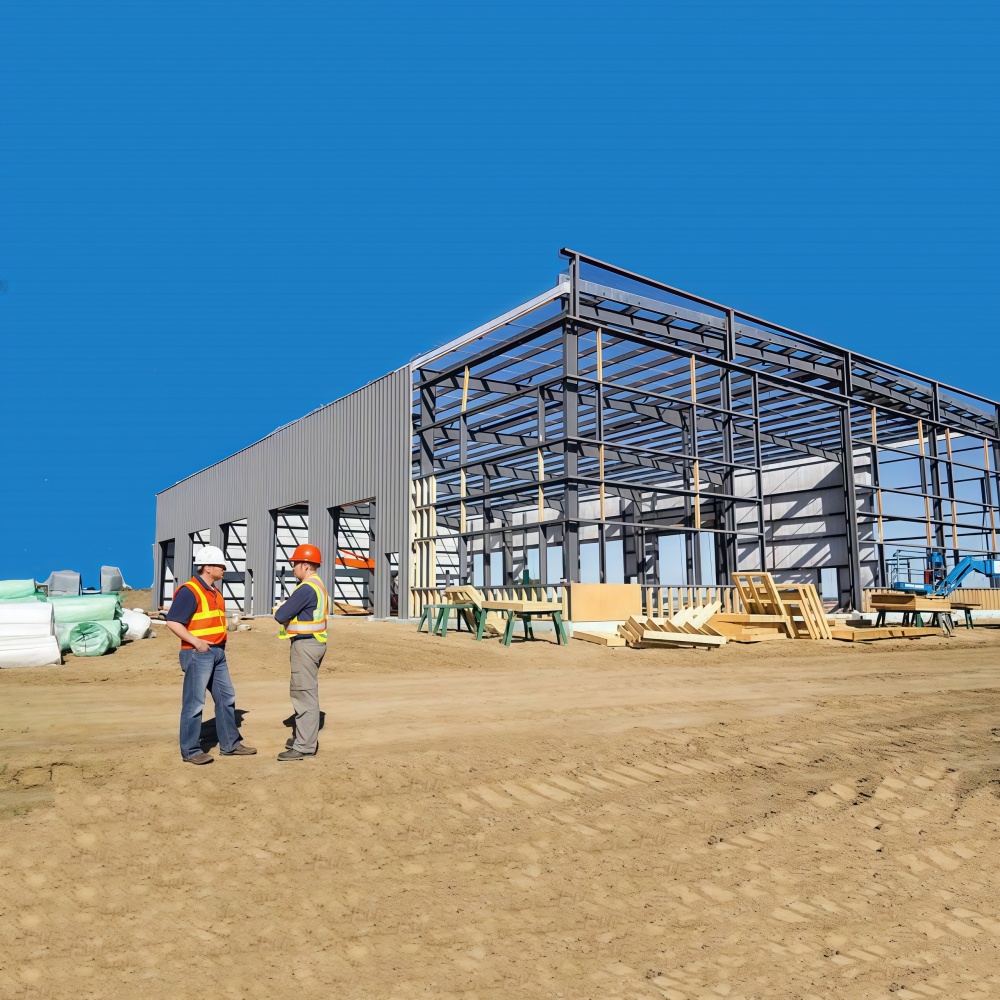

Span range of Steel structure plant

Small-span plant: usually refers to spans between 6 and 24 metres, mainly portal rigid frame, simple structure and dense support system.

Large-span plant: spanning more than 36 metres, requiring the use of mesh frames, suspension or arch structures, with fewer support points and requiring high-precision design

Material and load-bearing design of Steel structure workshop

Small-span plants of Steel structure workshop are mostly made of ordinary Q235 steel, with single-storey steel columns + steel beams for lightweight structures.

High strength steel (e.g. Q345) is required for large span Steel structure plant, and may be combined with pre-stressing techniques or composite trusses to enhance stability

Comparison of Functional Features and Advantages

Space utilisation of Steel structure plant

Space utilisation Suitable for zoned layouts, but small column spacing (6-8m) may restrict the placement of large equipment .

Construction period Lightweight components, high prefabrication rate, construction period is usually 1-3 months12.

Seismic resistance and durability Seismic performance is average, suitable for low intensity areas;

Large-span Steel structure plant

No or few columns design, open internal space, suitable for assembly line or heavy machinery layout.

Requires customised fabrication and complex lifting (e.g. moving platforms for bailey frames), construction period may reach 6-12 months.

Enhanced seismic resistance through flexible connections and dampers; requires regular maintenance (e.g., fireproof paint renewal) and can have a service life of up to 50 years.

Comparison of Application Scenarios of Steel structure workshop

Typical uses of small-span Steel structure workshop

Light industry: electronic assembly, food processing and other industries with small space requirements.

Warehousing and logistics: small warehouses, cold chain logistics transit stations, suitable for standardised rack layout.

Supporting buildings: such as factory office buildings, staff dormitories and other ancillary facilities.

Large-span plant core applications of Steel structure workshop

Heavy manufacturing: automobile manufacturing, aerospace field, need to accommodate large stamping equipment or complete production lines.

Public facilities: sports stadiums, exhibition centres (e.g. column-free dome design) with spans of up to 100m or more.

Special scenarios: aircraft maintenance hangars, shipyards, and other areas requiring super-tall heights (≥20 metres)

Suggestions for selection of Steel structure workshop

Economy first: if budget is limited and complex processes are not required, a small-span plant is more cost-effective.

Long-term planning consideration: Although the initial investment of large-span plant is high (about 1.2 times of concrete structure), the long-term operation cost can be reduced through space reuse.

Technological adaptation: pre-stressed truss or space mesh shell structure is recommended for spans >50m, which can reduce steel consumption by 10%-15%.