1. Steel Structure design allows for precision and technical optimisation

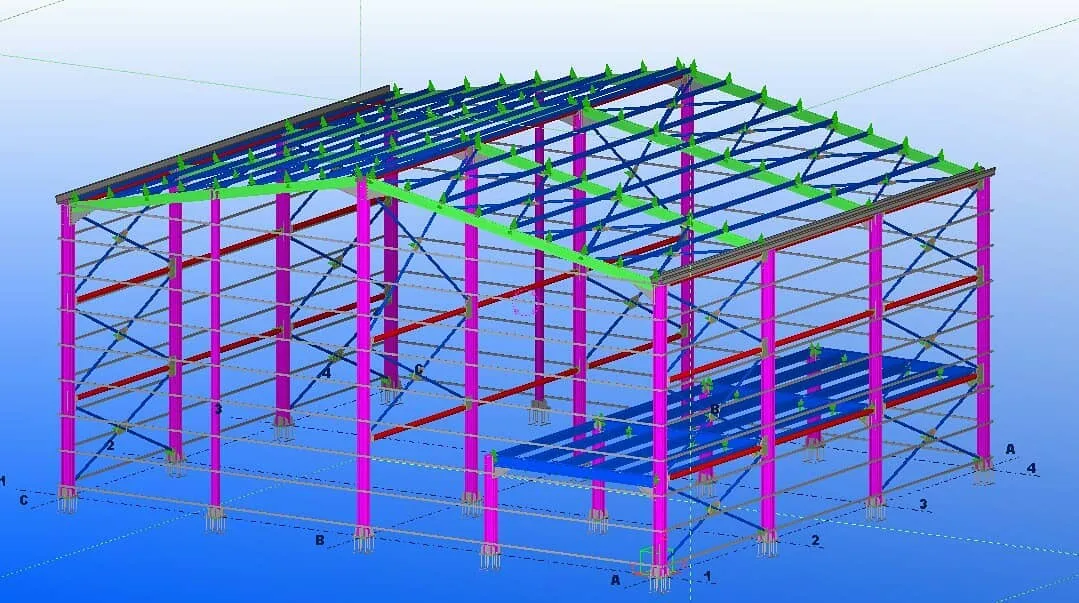

2. Design of steel to achieve millimetre-level accuracy of component dimensions and node configurations through 3D modelling technology (e.g. BIM) to ensure seamless connection between construction drawings and engineering entities

3.Design Service of Structure need to The synergistic value of a team of professionals

Five core strategies to reduce the cost of steel structure Design

1. Design of steel Node optimisation and simplification

Reduce redundant materials through accurate node design, for example, adopting standardised welded nodes instead of complex bolted connections, which can reduce the processing difficulty of components and the amount of fittings. Pre-embedded anchor bolts instead of traditional pre-embedded plates in high-rise buildings can reduce the cost of rework caused by construction errors, case data show that single node optimisation can save 276.4kg of steel.

2. Steel Structure design Material selection and dosage control

- Application of high-strength steel: Q345 steel is used to replace Q235 steel, which reduces the steel consumption by 15%-25%.

- Design of steel Section optimisation: Steel Structure design adjusting the section size of beams and columns through mechanical simulation to reduce redundant sections, typical projects can reduce the steel waste rate by 15%-30%.

- Design of steel Component segmentation optimisation: Steel Structure design reduce the number of steel column segments, Design of steel reduce the need for connection nodes and reinforcement equipment, a power plant project through segmentation optimisation to save 2 tonnes of steel, reduce 3,800 sets of bolts.

3. Design of steel Co-design of transport and construction

- Design of steel Transportation programme refinement: Design of steel optimize the size of components according to the load of transport vehicles and road conditions to avoid additional costs caused by over-limit transportation.

- Design Service of Structure Lifting process front: simulate the lifting path in the deepening stage to reduce the number of on-site assembling, and an assembly project shortened the construction period by 20% through the optimisation of the construction process.

4. Design Service of Structure Optimisation of structural system and layout

- Design Service of Structure Economic span selection: portal frame plant adopts 6-9m column spacing, which can balance steel consumption and construction efficiency and avoid excessive auxiliary materials such as purlins and crane beams.

- Design Service of Structure Accurate calculation of loads: load distribution is simulated by BIM model to optimize the beam and plate layout, reduce the phenomenon of over-allocation of floor thickness, and reduce the amount of concrete and steel reinforcement.

5. Design Service of Structure Digital and standardised management

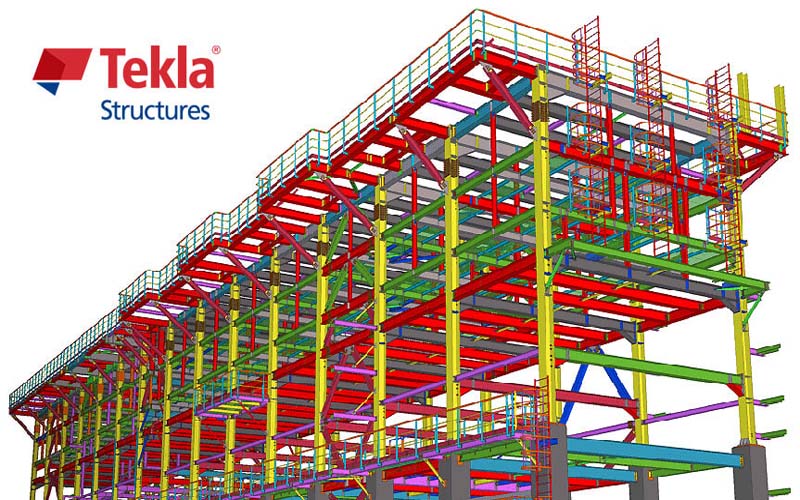

- Steel Structure design Application of BIM technology: Detect collision problems through 3D modelling, reduce on-site modification costs, cases show that rework costs can be reduced by 10%-15%.

- Steel Structure design Component standardisation: unify bolt specifications and node types to achieve factory assembly line production, a project through standardised design to reduce processing costs of more than one million yuan.

Design of steel achieves full chain cost control through technical optimisation (e.g. BIM simulation), process innovation (e.g. segmentation control) and resource integration (e.g. transport coordination). Choosing an ISO9001-certified deepening team ensures that design results are seamlessly integrated with construction and manufacturing to maximise cost savings.

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel construction for more than 10 years.

Our products cover all types of steel structure buildings, Design of Steel Structure, Deepening Structure Design including various prefabricated metal building warehouse, steel structure workshops, steel structure garages, steel structure poultry houses, steel structure prefabricated houses, etc.

We not only pay attention to the appearance of the product design, but also pay attention to the functionality and intelligence of the product. We advocate the concept of green building, using environmentally friendly materials, energy saving technology, and are committed to creating sustainable homes that meet the needs of future living. We have a passionate and creative team, including talented designers, engineers and technicians. The company continues to increase investment in research and development, actively introduce advanced technology at home and abroad, and is committed to improving the quality and intelligent level of products.