What are the common reinforcement methods for mesh frame steel structures?

What are the common reinforcement methods for mesh frame steel structures?

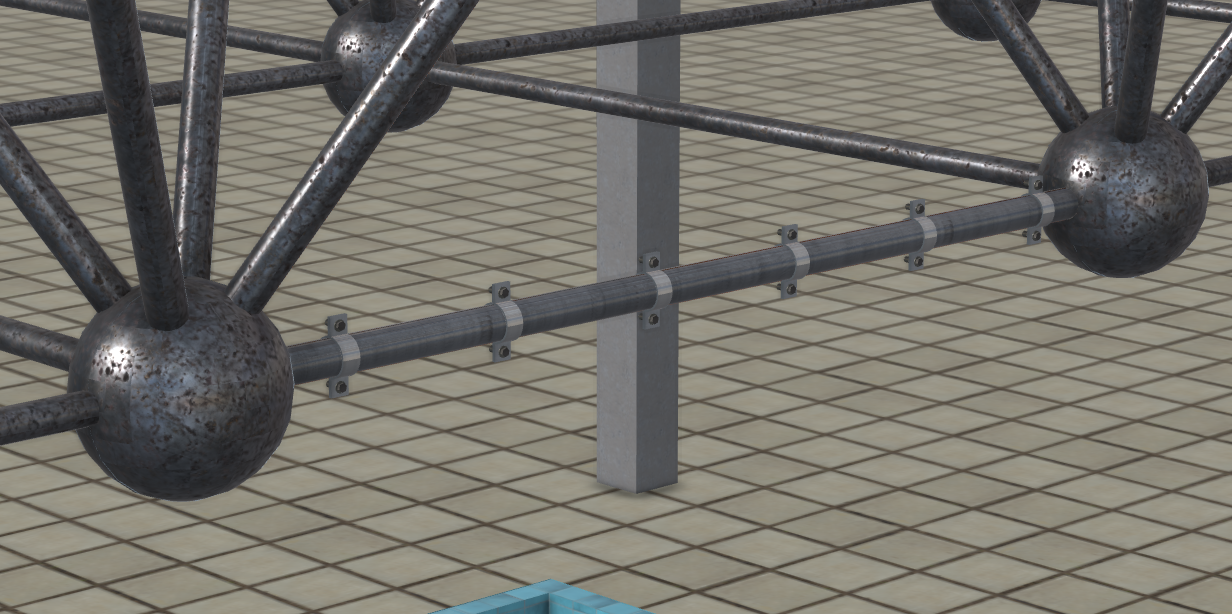

Casing Reinforcement of Mesh Frame Steel structure building

The larger steel pipe is ferrule outside the bar, fixed by clips and bolts compression, and the load carrying capacity is increased by the synergistic force of the inner and outer members. The Metal Building casing can be connected by applying adhesive steel glue. For non-bonded fixed connection reinforcement, the calculation, strength calculation only consider the original member of the cross-section, stability calculation consider the role of the new casing, generally only used for compression rod stability insufficient reinforcement.

Steel structure building Advantages: High economy, convenient construction, factory prefabricated. It can inhibit the buckling of rods and improve stability.

Metal Building Disadvantages processing, construction precision requirements are slightly higher.

2. Metal Building Welding for section reinforcement

Welded angles, channels or reinforcing steel pipes are connected to the original bars.

Advantages

Mature process, reliable quality and low cost. Can quickly improve the strength and stability of the section. Disadvantages

Welding heat-affected zone can easily lead to material property degradation or cracks. Fire operation requires shutdown protection, high risk

Steel structure building Advantages

Mature process, reliable quality and low cost. Can quickly improve the strength and stability of the section.

Metal Building Disadvantages

Welding heat-affected zone can easily lead to material property degradation or cracks. Fire operation requires shutdown protection, high risk

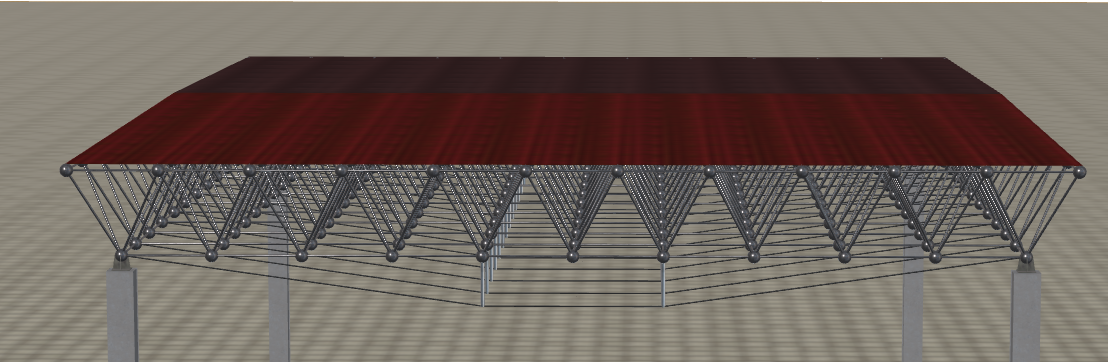

3. Steel structure building Prestressing reinforcement method

Metal Building Method

Adding prestressing cables and gussets, applying reverse loads to adjust the internal forces.

Steel structure building Advantages

Significantly improves overall stiffness and reduces deformation. No change to the original bars, flexible construction.

Disadvantages: Complex node design, precise control of pre-tensioning required. Long-term monitoring of prestress relaxation.

4.Metal Building Rod Replacement Method

Method

Replacement of higher strength (e.g. Q345 for Q235) or larger cross-section bars.

Advantages

Directly enhance the bearing capacity, the effect is clear.

Metal Building Disadvantages

High construction risk due to the need to set up temporary support.

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel construction for more than 10 years.

Our products cover all types of steel structure buildings, including various Metal Building , steel structure workshops, steel structure garages, steel structure poultry houses, steel structure prefabricated houses, etc.

We not only pay attention to the appearance of the product design, but also pay attention to the functionality and intelligence of the product. We advocate the concept of green building, using environmentally friendly materials, energy saving technology, and are committed to creating sustainable homes that meet the needs of future living. We have a passionate and creative team, including talented designers, engineers and technicians. The company continues to increase investment in research and development, actively introduce advanced technology at home and abroad, and is committed to improving the quality and intelligent level of products.