Why steel poultry houses are so popular in Africa

Why Steel Structure poultry are so popular in Africa?

1.Price advantage: ideal for the African market Steel Structure Building

Steel Structure poultry are the preferred option for agricultural construction in Africa because of their economy. In terms of material costs, Steel Structure Building is strong and lightweight (Q235/Q345 grade steel is predominant), reducing building material costs by 30%-50% compared to traditional concrete buildings). Transportation costs are high in Africa, and the modular design of the Steel Structure Building components allows a 40-foot tall container to carry 700-800 square metres of material, significantly reducing shipping costs. In addition, the steel is over 90 per cent recyclable, which meets the need for long-term sustainable development in Africa.

2.Steel Structure Building features: adapted to the complex environment in Africa

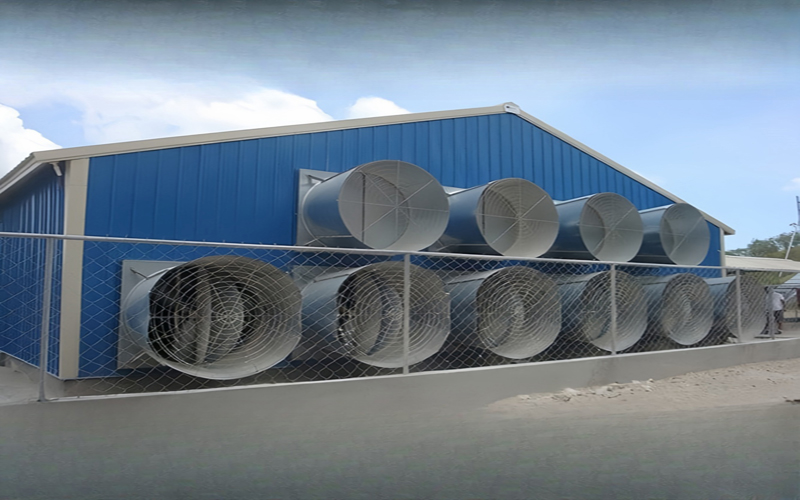

High strength and stability: the Steel Structure poultry is made of H-beam or square tube frames, with a wind pressure resistance of 0.6kN/m² and a seismic rating of 8. It can withstand sandstorms and seasonal rainstorms, which are common in Africa.

Flexible customisation: sandwich panels (EPS/rockwool) or single-layer corrugated steel sheets are available for roofs and walls, with insulated sandwich panels recommended for the high temperatures of sub-Saharan regions, and economical veneers for arid regions of North Africa.

Strong weather resistance: the steel is galvanised or coated with anti-corrosion coating, with a service life of 30-50 years, adapting to the harsh environments of humidity, heat and salinity in Africa.

3.Construction features of Steel Structure poultry: efficient deployment and low technical threshold

Prefabricated production: the components are mechanically processed in the factory, the error is controlled within ±2mm, and only need to be assembled on site according to the number, the installation cycle of 1500 square metres poultry house is about 30 days (8-10 workers).

Simplified operation: Chinese and English installation manuals and video guides are provided. Local African workers can complete the erection after a short period of training and no heavy equipment is required.

Climate-adapted construction: dry operation is not affected by the rainy season, and the open structure design (e.g. wire mesh wall + roller shutter door) facilitates natural ventilation and reduces energy consumption.

African applicability cases of Steel Structure Building and optimisation solutions

Taking a 10,000 chicken farm in Nigeria as an example, the Steel Structure poultry adopts the following configuration:

Size: 60m×12m×4m (eaves height), H-beam main beam + rock wool sandwich panel;

Cost: unit price of about 210 yuan/square metre (including automated feeding system);

Maintenance: free replacement of wearing parts during the three-year warranty period, remote technical support response time <24 hours.

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel construction for more than 10 years.

Our products cover all types of steel structure buildings, including various prefabricated metal building warehouse, steel structure workshops, steel structure garages, steel structure poultry houses, steel structure prefabricated houses, etc