Why packing container house are rapidly spreading across Russia

In the context of the rapid development of assembly construction, Packing Container House are becoming an innovative force in the field of temporary construction by virtue of their industrialised production characteristics and flexible combination advantages.

Materials: the golden combination for performance optimisation

Main frame of Packing Container House

Cold rolled steel profiles of 1.5-2.5mm thickness are used to form the main structure of the box through robotic welding. The columns and beams are connected by mortise and tenon joints with galvanised bolts, and the overall compressive strength reaches 0.5KN/m², which can withstand strong winds of grade 8.

Enclosure system of Packing Container House

- 50/75/100mm thick sandwich panel (rock wool/glass magnesium/polyurethane core optional)

- Double-sided 0.3-0.6mm colour steel sheet cladding, fire rating A grade

- Wall panels and frames are fixed with hidden clips to achieve seamless splicing.

Window and door system of Packing Container House

Standard with 120 series broken bridge aluminium casement windows, with triple advantages:

- Thermal insulation coefficient ≤2.8W/(m²-K), saving 40% energy compared with traditional plastic steel windows.

- Built-in 304 diamond mesh, realising the double demand of anti-theft and ventilation.

- Embedded installation of window frame and box, airtightness up to national standard grade 8.

Core Advantages of Packing Container House

Industrialised production characteristics

The standardised packing box adopts modular design, and the prefabrication rate of the factory reaches 92%. 6-8 basic units can be composed of office, accommodation and other functional spaces, and the delivery cycle of 7-15 days is 60% shorter than that of the traditional movable house.

![]()

Scenario Adaptability

Through the combination mode of ‘main box + extension box’, it can meet the following requirements:

- Site camp: complete the construction of 200m2 camp in 3 hours.

- Emergency command: snow load resistance up to 1.5KN/m².

- Commercial space: the external finish supports the customisation of aluminium composite panel/wood grain transfer printing.

Application Cases

A photovoltaic power station project used 86 packed box units to build a complete camp containing a

control room, a material store, and a staff dormitory in 15 days.

The acoustic performance of the broken-bridge aluminium windows (35dB noise reduction) effectively so-lved the noise interference in the equipment area.

This steel + sandwich panel structure packing box solution is redefining the quality standards of

temporary construction. With the continuous iteration of modular technology, the future of the packing

house will be a deep evolution towards intelligence and greenery

![]()

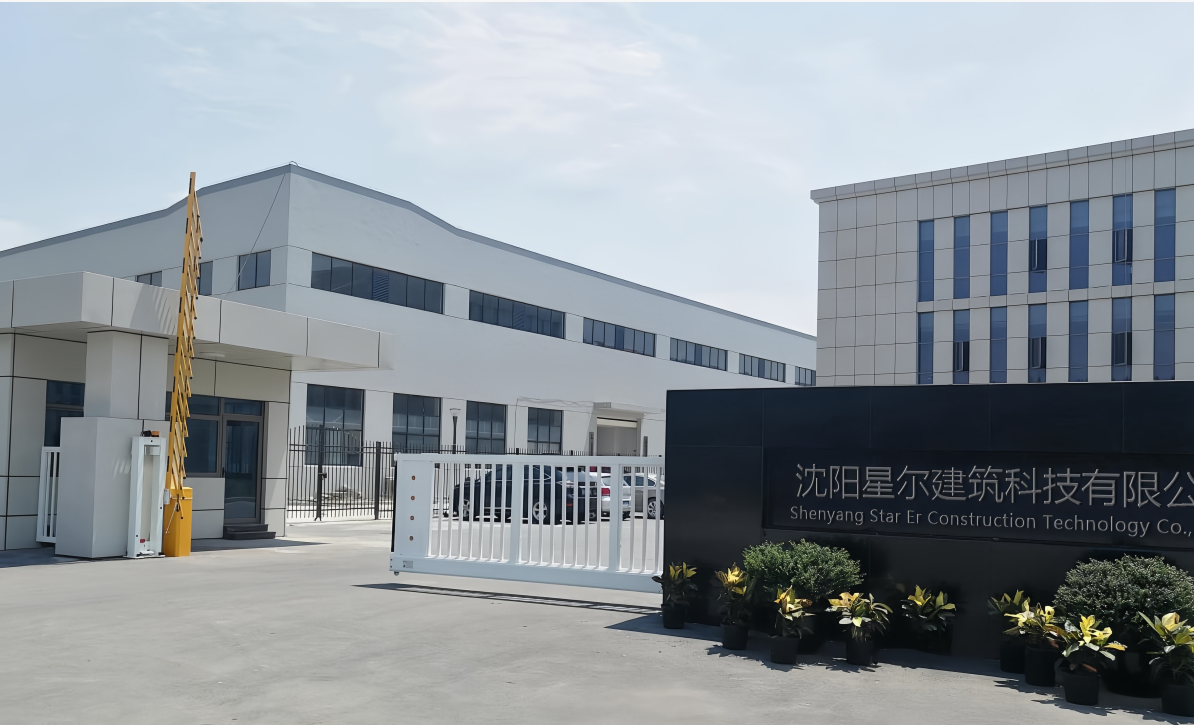

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel construction for more than 10 years.

Our products cover all types of steel structure buildings, including various prefabricated metal building warehouse, steel structure workshops, steel structure garages, steel structure poultry houses, steel structure prefabricated houses, etc.