The core material of steel structure warehouse buildings is steel, mainly high-quality steels such as Q235B and Q345B. Steel has high strength, good toughness and ductility, and can withstand large loads and deformations. In addition, steel also has characteristics such as corrosion resistance and fire resistance. Through surface treatments (such as hot-dip galvanizing, painting, etc.), its service life can be further extended.

(1)

Efficient Construction: The components of steel structure warehouse buildings are prefabricated in the factory, and only assembly is required on site, greatly shortening the construction period, which is especially suitable for projects urgently needing to be put into production.

(2) Environmentally Friendly and Energy-Saving: Steel Structure Buildings can be recycled, reducing construction waste and conforming to the green environmental protection concept. Meanwhile, the design of steel structure buildings facilitates the installation of thermal insulation materials and daylighting systems, reducing energy consumption.

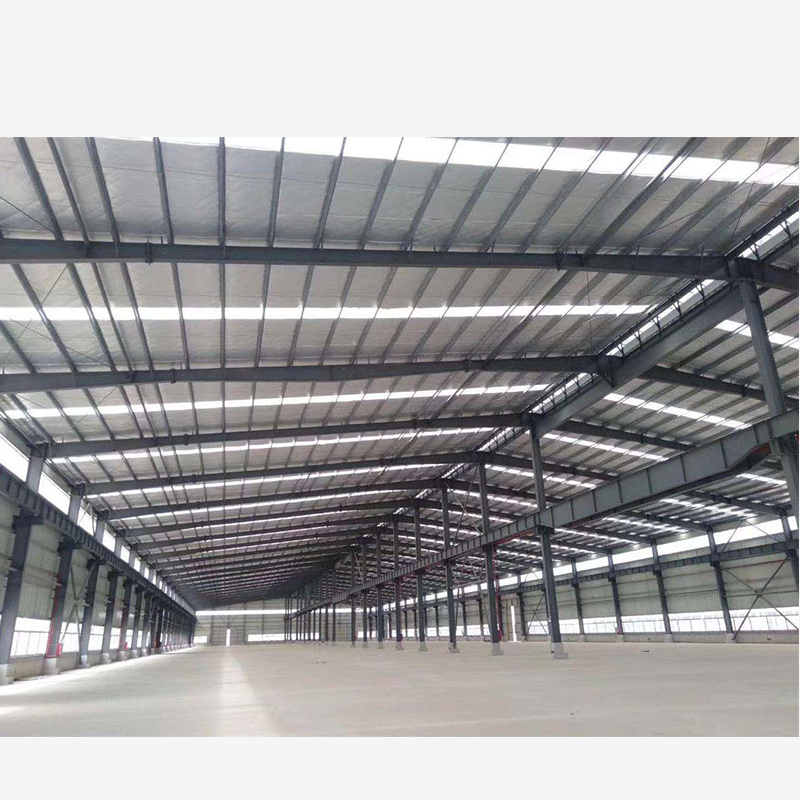

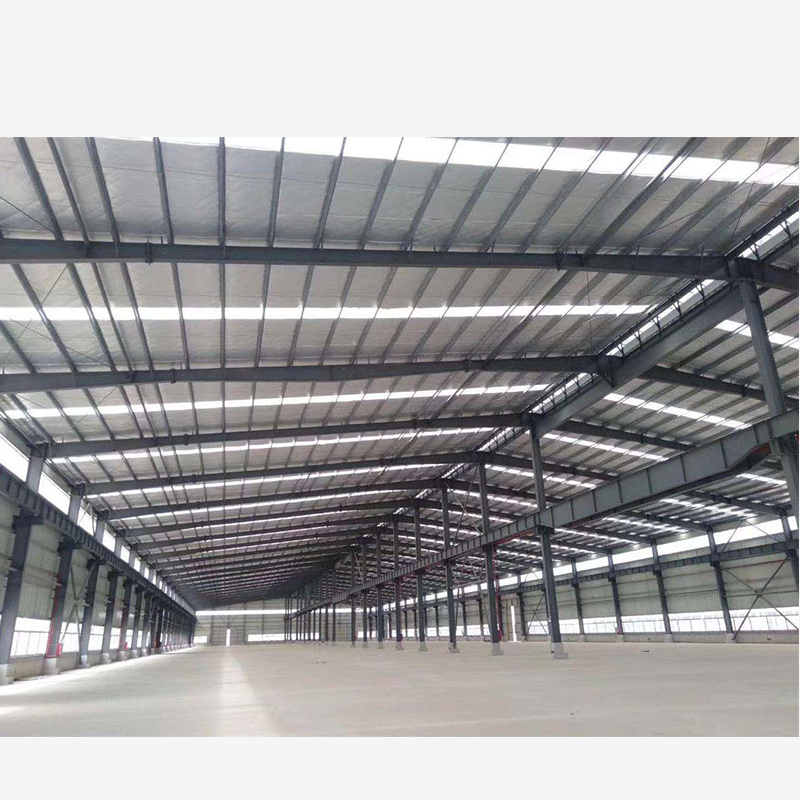

(3) Flexible Space: There are no or few columns inside the steel structure building, resulting in a high space utilization rate and allowing flexible layout adjustments according to production requirements.

(4) Steel Structure warehouse have Strong Seismic Performance: The toughness of steel enables steel structure buildings to have good seismic performance during earthquakes, ensuring the safety of personnel and equipment.

The assembly of steel structure

warehouse buildings mainly consists of the following steps:(1)

Foundation Construction: Pour concrete foundations to ensure bearing capacity and stability.

(2)

Steel Column Installation: Hoist the prefabricated steel structure buildings columns into place and correct their verticality.

(3)

Steel Beam Installation: Connect the steel beams and steel columns with high-strength bolts to form a stable frame structure.

(4) Enclosure Structure Installation: Install color steel plates or sandwich panels for walls and roofs to ensure the sealing and thermal insulation of the Steel Structure Buildings.

Since the components of steel structure buildings adopt standardized designs, the assembly process is fast and efficient, and the quality is controllable.

Although the initial investment in steel structure factory buildings is slightly higher than that of traditional concrete structures, in the long run, its cost performance is higher. This is mainly reflected in the following aspects:

(1) The short construction period reduces labor costs and interest expenses.

(2) The low maintenance cost, as the durability of steel reduces later repair expenses.

(3) The high space utilization rate provides enterprises with more usable area, indirectly enhancing economic benefits.

Steel structure are widely used in industries such as manufacturing, warehousing and logistics, automobile manufacturing, and food processing. Their flexible design and efficient construction methods can meet the needs of different enterprises and have become the mainstream choice for modern industrial architecture.

Steel structure, with their characteristics of high-strength materials, efficient construction, environmental protection and energy conservation, and price advantages, have become the preferred option for modern industrial architecture. Whether it is a new project or the renovation of an old factory building, steel structure factory buildings can provide reliable and efficient solutions for enterprises. If you are considering building an industrial factory building, a steel structure factory building is undoubtedly a choice worth considering